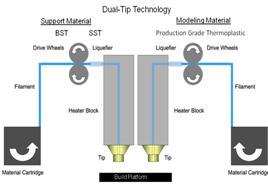

1. Fused Deposition Modeling (FDM): Plastic Filament Extrusion Based technology

Fused deposition modeling (FDM) was developed by Mr. Scott Scott Crump in the late 1980s and was commercialized in 1990 by Stratasys. Fused Deposition Modeling (FDM) creates 3D prototypes by heating and extruding a filament of plastic material. In a typical FDM system, the extrusion nozzle moves over the build platform in X and Y directions. This “draws” a cross section of an object onto the platform. When this thin layer of plastic cools and hardens, it immediately binds to the layer beneath it. Once a layer is completed, the base is lowered slightly, making way to add the next layer of plastic.

This is most widely used and affordable technology in 3D Printing. As it uses real engineering grade thermoplastics, parts built are more stronger, durable and widely used for functional testing applications. You can build parts directly into ABS, polycarbonate, nylon and various other materials. Due to its simplicity and ease of use; these machines are office friendly machines and can be installed in Design office.

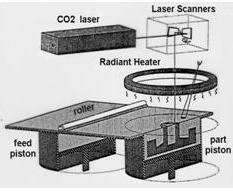

2. Selective Layer Sintering (SLS) – Powder Based 3D Printing

Selective Laser Sintering (SLS) was developed and patented by Dr. Carl Deckard and academic adviser, Dr. Joe Beaman at the University of Texas at Austin in the mid-1980s, under sponsorship of DARPA.

In Selective Layer Sintering, a computer controlled laser pulses down on the platform, tracing a cross-section of the object onto tiny particles of plastic, ceramic or glass. The laser heats the powder either to just below its boiling point (sintering) or above its boiling point (melting), which fuses the particles in the powder together into a solid form. This process continues until the entire object has been printed.

SLS parts are widely used for snap-fit applications. As powder is used for printing the parts; special care needs to be taken while handling these machines. These machines cannot be used in office environment and needs a special environment.

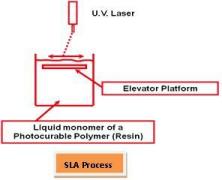

3. Stereolithography (SLA) – Liquid Based 3D Printing

The first commercial 3D printer was based on a technique called Stereolithography, invented by Charles Hull in 1986. It is also called as SLA (SteroLithographyApparatus)

In Stereolithographic 3D printers, successive layers of fluid resin are hardened using UV rays or lasers. After each layer is fused, the perforated platform is lowered very slightly and another slice is traced out and hardened by the UV / laser. This process is repeated until a complete object has been printed.

This technology is widely used in jewellery industry due to its fine surface finish and accuracy. It is one of the most expensive technologies to use. Objects printed cannot be used directly as it needs post-curing operation to strengthen the parts.

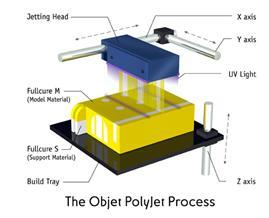

4. PolyJet / InkJet 3D Printing

PolyJet inkjet technology works by jetting state of the art photopolymer materials in ultra-thin layers (16µ) onto a build tray layer by layer until the part is completed.

Each photopolymer layer is cured by UV light immediately after it is jetted, producing fully cured models that can be handled and used immediately, without post-curing. The gel-like support material, which is specially designed to support complicated geometries, is easily removed by hand and water jetting.

This technology helps us in printing rigid parts, Transparent Parts, Rubber like / Flexible parts required for prototyping applications. This is the only technology which can print multi-materials and multi-colors in a single build. Again, Stratasys is a major player in this field. The company has a significant market share for Polyjet printers in India.

Find the Manufacturing Process that suits you best

For low volume manufacturing, high complexity parts, fully assembled components, parts that need to be customized, or that you simply need your part FAST, using a Professional 3D printer is the best choice. However, if material properties and surface finish are of critical importance, your complexity is low, and your manufacturing volume is low, then CNC machining may be a better option. For high volume manufacturing of relatively simple components, set your aim for a process like injection molding or forming. Still confused? For help selecting the correct process for your application, check out the selection tool below.

cOMPARISON.JPG

Source: http://www.designtechsys.com/articles/3d-printing-technologies.php

Source: http://www.sculpteo.com/en/3d-printing/3d-printing-and-traditional-manufacturing-processes/